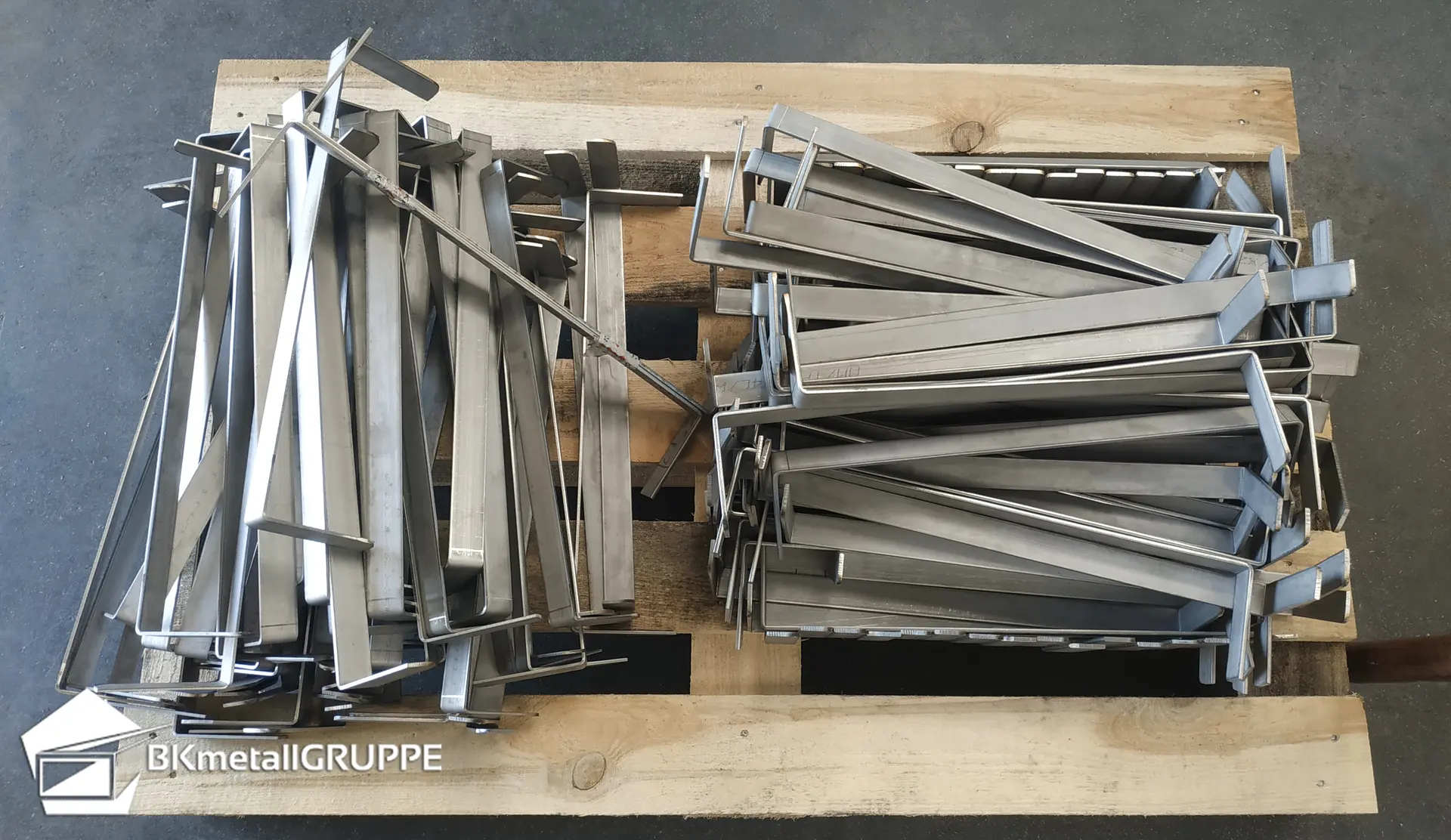

Semi-Finished Products

We manufacture precision semi-finished products from stainless steel and other metals for the food, pharmaceutical, chemical, and construction industries. We offer laser cutting, CNC bending, TIG/MIG welding, and surface finishing (powder coating, galvanizing). We ensure repeatability, high quality, order flexibility, and short delivery times tailored to individual needs.

We specialize in the production of stainless steel semi-finished products and other metals, which are used across various industries – from food and pharmaceutical to chemical and construction. We offer both small and large-scale series, customized to the specific needs of our clients. Every stage of production is carried out with the utmost care, adhering to technical requirements and quality standards.

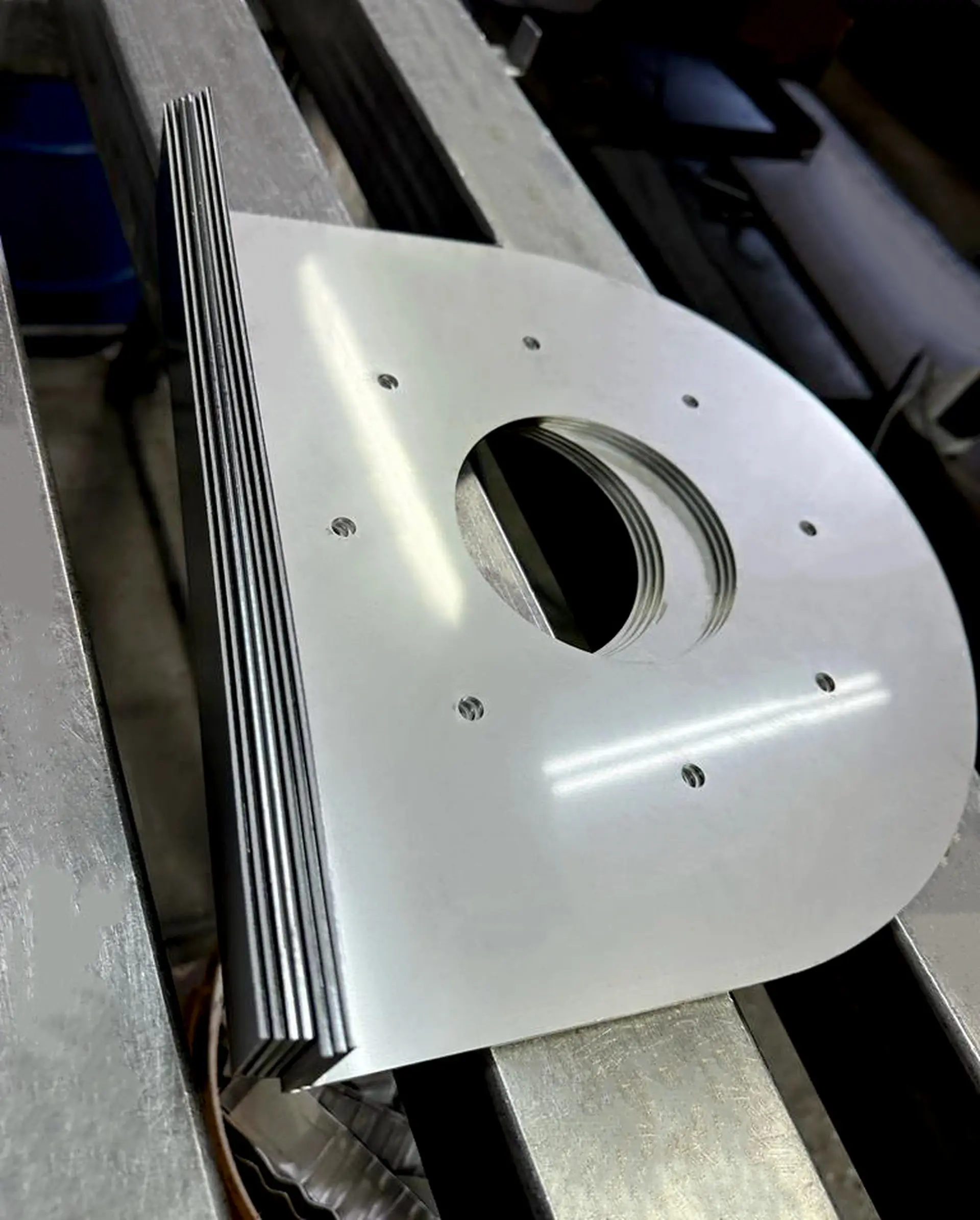

Our semi-finished products are created using modern technologies. Stainless steel is laser-cut, ensuring precise shapes and minimal material waste. The components are then bent on CNC press brakes, guaranteeing consistent forms and high-quality execution. We also provide TIG and MIG welding, depending on the type of structure and its intended use.

Additionally, at the client's request, semi-finished products can undergo powder coating, galvanizing, or other surface protection methods. This ensures not only durability but also aesthetic finishing, which is crucial in industries with high hygiene and visual standards.

We collaborate with both large enterprises and smaller companies, offering flexibility in order volumes, short lead times, and comprehensive technological support. Our team consists of experienced professionals who are ready to advise on the selection of appropriate materials and design solutions.

Trust a reliable partner and choose stainless steel semi-finished products that meet the highest quality standards – from concept through production to the delivery of finished components.