Welding

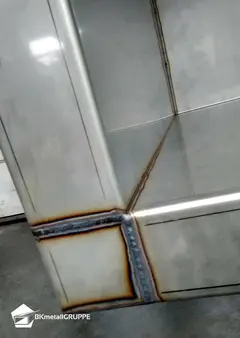

We specialize in precise stainless steel welding using TIG, MIG/MAG, and spot welding methods, ensuring durable and aesthetic welds for the food, pharmaceutical, and chemical industries. We offer welding of structures, pipelines, tanks, enclosures, and catering equipment. We guarantee high quality, technical consultancy, and weld inspection, including NDT testing.

Welding is one of the key processes in metal processing, and for years, we have specialized primarily in stainless steel welding. We also perform connections in carbon steel, but stainless steel remains our core expertise. Thanks to our extensive experience and modern technological facilities, we guarantee the highest quality and durability of welds, even in the most demanding projects.

Stainless steel, due to its properties – corrosion resistance, high durability, and aesthetic appearance – requires exceptional precision and the use of appropriate welding technologies. We weld using TIG, MIG/MAG, and spot welding methods, depending on the type of component, its purpose, and structural requirements. We place particular emphasis on the cleanliness of the process, which is essential in industries such as food, pharmaceutical, and chemical.

We offer welding of:

- structures and machine components made of stainless steel,

- pipelines and technological installations,

- enclosures, cabinets, tables, and catering equipment,

- tanks, railings, and other functional structures,

- steel components for further processing or assembly.

Each project is treated individually, with technical consultancy and the selection of the best solutions provided. We work both on client-provided documentation and handle projects comprehensively – from design to the finished product. We use top-quality welding materials and continuously monitor the quality of the connections made – visually and, if necessary, through non-destructive testing methods (NDT).

If you value solid and aesthetic stainless steel connections, we are your partner. Our welds are not only durable but also meet stringent industry standards.